OUR TECHNOLOGY

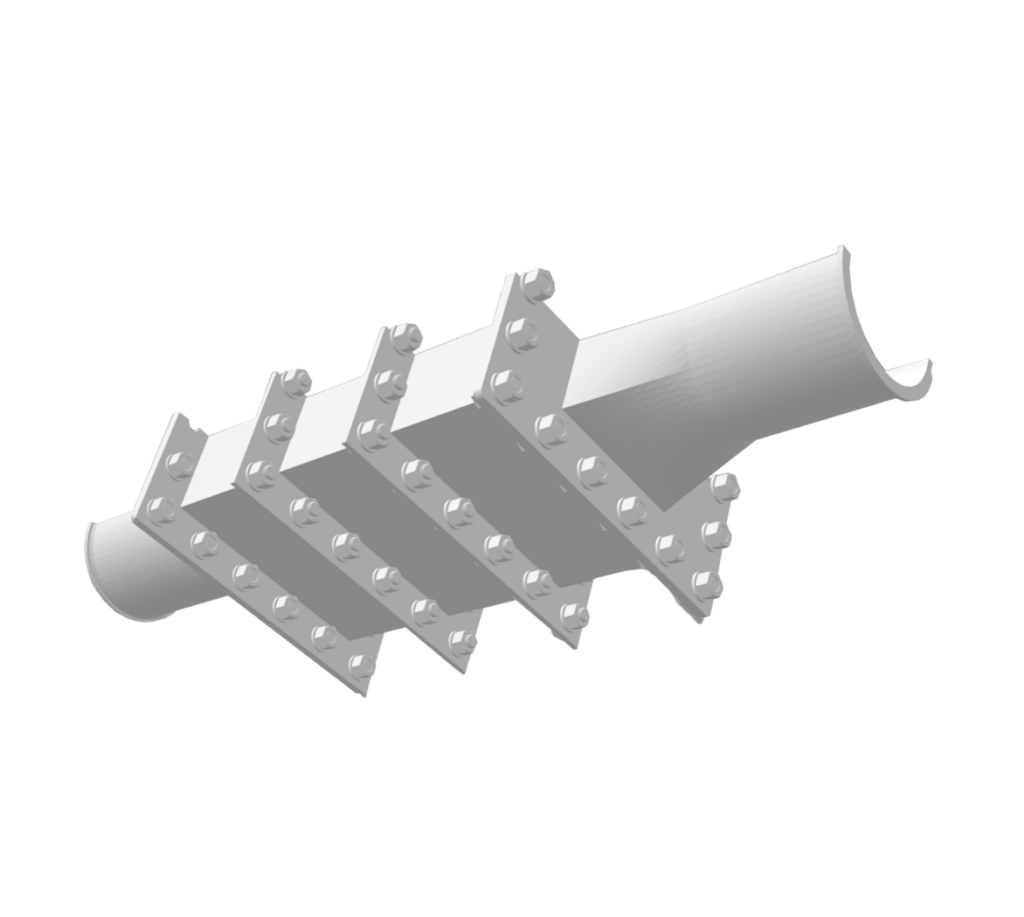

The core of Prodea Non-Thermal Plasma reactors is made from a novel plasma discharge material.

Our technology is based on three key patents, resulting from Prodea R&D, which deal with all the materials processing steps and the design of reactor.

The plasma properties, stemming from the microstructure of the materials, in conjunction with the reactor design provide a technological breakthrough as illustrated by the high abatement performances and energy efficiency which are achieved.

our performances

If you are curious , we propose you to explore in details our performances

by downloading our PDF.

The planet thanks you for your interest in Prodea Depolluting technology ! 🌏

specificities of our material

THE FABRICATION OF THE REACTOR CORE (THE NOVEL ELECTROCERAMIC ACTING AS PLASMA DISCHARGE MATERIAL) HAS BEEN SUCCESSFULLY TACKLED, THANKS TO PRODEA WORKS WHICH DEAL WITH:

– THE ORIGINAL PROCESSING ROUTE OF THE ELECTROCERAMIC POWDER COMPOSITE

– THE SETTING-UP OF THE DENSIFICATION TECHNOLOGY (SINTERING TECHNOLOGY)

THE CONVENTIONNAL SINTERING TECHNIQUES AND, MOST IMPORTANTLY, THE EMERGING SPARK PLASMA SINTERING TECHNOLOGY (SPS) HAVE BEEN UTILIZED.

NEW OPPORTUNITIES, PARTICULARLY THOSE RELEVANT TO PROCESS SIMPLIFICATION, THAT ARE POTENTIALLY PROVIDED BY THE SPARK PLASMA SINTERING TECHNOLOGY, HAVE BEEN INVESTIGATED.

THE MAIN DRAWBACKS OF THE SPARK PLASMA SINTERING TECHNOLOGY HAVE BEEN CIRCUMVENTED. HENCE, THE FABRICATIONS OF LARGE COMPONENTS (WITH DIAMETERS UP TO 150 MM, AS REQUIRED BY THE REACTOR DESIGN), HAVING THE DESIRED PROPERTIES, ARE MADE POSSIBLE.